Precision in additive manufacturing translation is not optional—it’s a necessity.

Whether you’re producing technical manuals, compliance documents, or engineering specifications, even minor errors in translation can lead to production delays, regulatory non-compliance, or costly rework.

Additive manufacturing is built on innovation, precision, and technical expertise, and the same level of rigor must apply to the translation of its critical documentation.

Industry-specific terminology, evolving standards, and multilingual collaboration all add layers of complexity, making generic translation solutions ineffective.

To achieve consistency and accuracy, companies need a translation approach that aligns with their engineering workflows. This means leveraging industry-specialized linguists, implementing terminology management systems, and integrating translation quality control into existing documentation processes.

In this guide, we’ll explore key strategies to safeguard accuracy in additive manufacturing translation.

You’ll learn how to mitigate risks, improve communication across global teams, and ensure that your technical content remains as precise as your manufacturing processes.

Let’s dive in.

What is additive manufacturing?

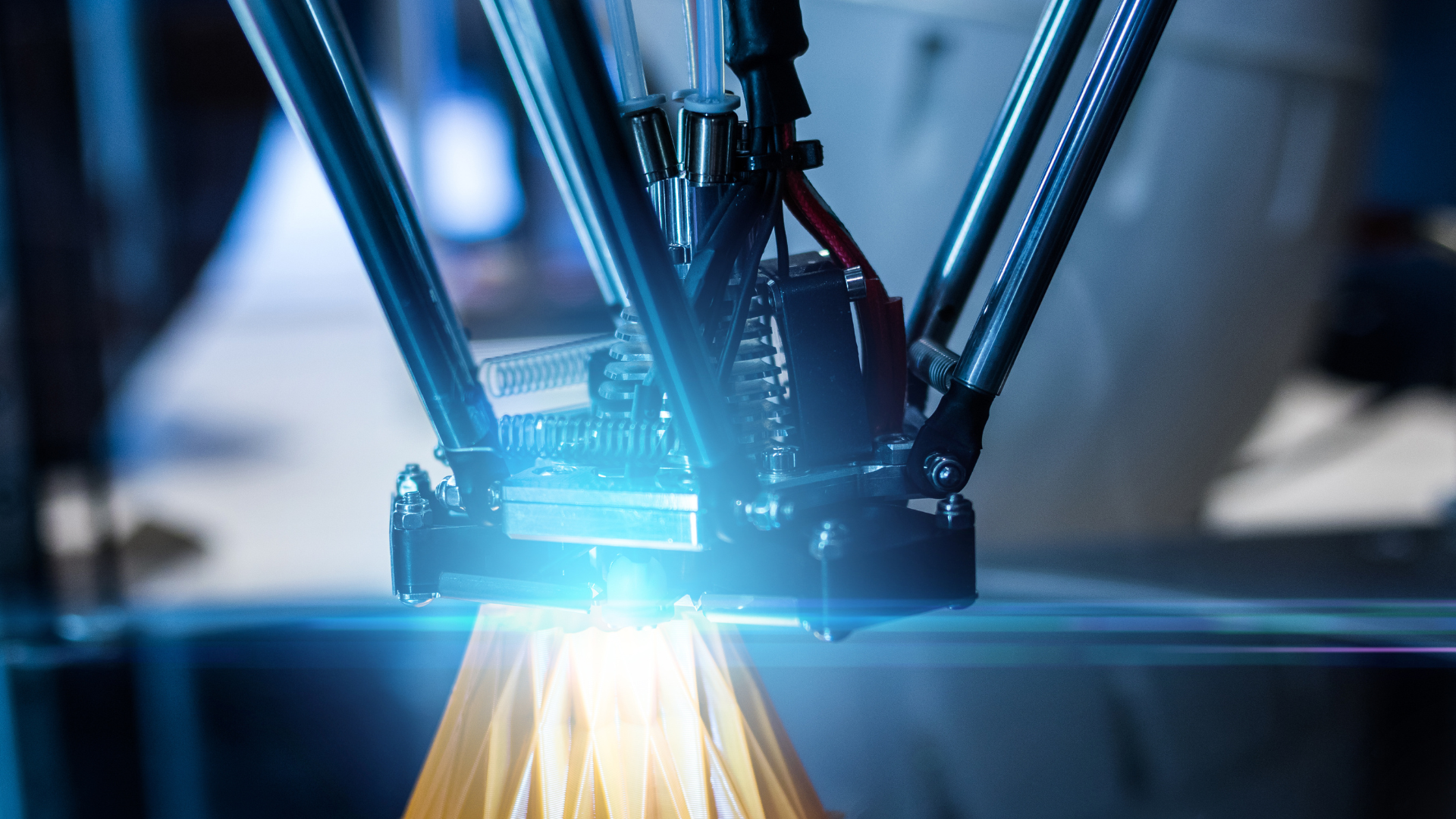

Additive manufacturing, commonly known as 3D printing, is a transformative approach to production that builds components layer by layer from digital models.

Unlike traditional subtractive manufacturing methods, which cut or shape materials from a solid block, additive manufacturing precisely deposits material where needed.

This process enables complex geometries, reduces material waste, and allows for rapid prototyping and on-demand production.

Industries ranging from aerospace and automotive to healthcare and industrial tooling rely on additive manufacturing for innovation and efficiency.

Companies use it to create lightweight components, custom medical implants, and intricate parts that would be difficult or impossible to produce with conventional methods.

However, the complexity of this technology extends beyond engineering—it also affects the way technical information is communicated.

Additive manufacturing documentation includes specifications, process guidelines, safety instructions, and compliance reports, all of which must be translated with accuracy to maintain consistency across global teams and markets.

Any misinterpretation of terminology or process details can lead to production errors, compliance issues, or safety risks.

This is why specialized translation in additive manufacturing is essential for companies operating in international markets.

Why accuracy matters in additive manufacturing translation

Precision is at the core of additive manufacturing, and the same level of accuracy must extend to the language used to document and communicate its processes.

Whether it’s material specifications, machine calibration guidelines, or safety procedures, every term carries weight.

And slight deviation in translation can lead to costly production errors, regulatory non-compliance, or even safety risks.

But when it comes to additive manufacturing, precision isn’t limited to the machines layering material or the engineers designing intricate components. It extends to the words used to describe every step of the process.

Translation in this field carries a unique weight—get it wrong, and the consequences ripple through production lines, compliance efforts, and even client relationships.

I’ve seen firsthand how a poorly translated technical manual can halt a project, forcing teams to backtrack and troubleshoot errors that could have been avoided.

In additive manufacturing, we’re dealing with complex concepts like powder bed fusion, material extrusion, or topology optimization.

These aren’t terms you can approximate.

A translator unfamiliar with the nuances might confuse “sintering” with “melting,” leading to incorrect machine settings or material choices.

For small and medium enterprises looking to expand globally, this kind of mistake can erode trust with international partners or regulators who rely on flawless documentation to greenlight a product.

Accuracy also ties directly to safety and efficiency.

Think about a maintenance guide for a 3D printer handling titanium powder. If the translation muddies critical instructions—like proper ventilation protocols or powder handling procedures—the result could be costly downtime or, worse, a hazardous incident.

I’ve worked with clients who’ve had to redo entire batches of components because a misinterpreted tolerance specification slipped through the cracks.

That’s time, money, and reputation on the line.

And the challenge magnifies when you consider the regulatory landscape.

Standards like ISO 13485 for medical devices or AMS7002 for aerospace components demand precise language in every market. A translation that strays from the original intent risks non-compliance, delaying certifications or market entry.

For startups and consultants, who often operate on tight timelines and budgets, these setbacks can be make-or-break.

However, what sets apart a reliable translation in this space is a deep grasp of the technical terrain.

It’s about knowing the difference between “layer thickness” and “build height” or understanding why “post-processing” isn’t interchangeable with “finishing.”

I have spent years honing this expertise, bridging the gap between engineering precision and linguistic clarity.

It’s not enough to be bilingual—success here demands a translator who can think like a manufacturer, anticipate the end user’s needs, and deliver documentation that’s as dependable as the parts being produced.

That’s the foundation for thriving in a global market.

Common challenges in additive manufacturing translations (and how to overcome them)

As you can see, translating for additive manufacturing isn’t a walk in the park.

The field is a maze of specialized terms and processes, and even small missteps can throw a wrench into a project.

One hurdle I see often is the sheer complexity of the vocabulary. Words like “binder jetting” or “directed energy deposition” don’t have direct equivalents in every language, and generic translators might stumble, producing vague or outright wrong terms.

I’ve had clients share stories of manuals where “curing” was swapped with “hardening,” leaving operators scratching their heads and parts failing quality checks.

The fix?

Work with translators who live and breathe manufacturing—they’ll know when to adapt a term or create a precise workaround that keeps the meaning intact.

Another sticking point is consistency.

In additive manufacturing, you’re often juggling multiple documents—design specs, user guides, safety protocols—all needing to align perfectly.

A term like “overhang” might pop up across these files, and if it’s translated differently each time, confusion creeps in fast.

I’ve seen this trip up SMEs expanding into new markets, where uneven terminology slowed down training and production.

The way around it is simple but effective: build a glossary specific to your project and stick to it.

I do this for clients all the time, ensuring every translator is on the same page, no matter the language.

Cultural nuances can also muddy the waters.

A phrase that’s crystal clear in English—like “run a test build”—might lose its punch or practicality when translated literally into, say, Japanese or German.

This isn’t about language alone; it’s about how engineers in different regions think and work.

I remember a case where a client’s instructions for “bed adhesion” baffled a European team because the phrasing didn’t match their local workflow.

Overcoming this means anticipating the end user’s perspective, tweaking the translation to fit their context without losing the technical core.

Then there’s the pressure of tight deadlines.

Startups and consultants in this space often race to get products to market, and translation can feel like a bottleneck.

Rushing it, though, risks errors—like swapping “tensile strength” for “yield strength”—that could derail certifications or customer trust.

The practical move here is to plan ahead and partner with a team that can scale with your timeline, not just churn out words.

We’ve streamlined workflows for clients by prioritizing key documents and using tools to catch inconsistencies early, keeping projects on track.

These challenges aren’t insurmountable, but they demand more than off-the-shelf translation solutions.

It takes a blend of technical know-how, attention to detail, and a real understanding of what’s at risk in additive manufacturing.

That’s where specialized expertise makes the difference—turning potential headaches into smooth, reliable communication across borders.

How inconsistent translations impact your additive manufacturing workflow

When translations falter, the fallout isn’t subtle. I’ve seen inconsistent terms sneak into technical docs and throw entire teams off balance.

Take something like “layer resolution.” If it’s translated one way in the design specs and another in the operator manual, you’ve got engineers chasing different targets.

The result?

Parts that don’t meet spec, wasted material, and a scramble to figure out where the disconnect happened.

This kind of hiccup hits hard in production timelines.

Imagine a startup racing to ship a prototype to an overseas client. The build instructions use “support structure” in English, but the German version flips between two terms with slightly different meanings. Operators hesitate, second-guess, or worse—build it wrong.

I’ve had clients tell me about delays stretching days because they had to verify intent with the original team.

For SMEs with lean resources, that’s a costly detour.

Regulatory compliance takes a hit too.

Standards like ISO 17296 demand uniformity in how processes are described. If “powder recoating” shifts meaning across translations, you risk failing an audit or slowing down certification.

I worked with a medical device maker once whose translated quality control guide mixed up “validation” and “verification.” It wasn’t caught until a regulator flagged it, pushing their market entry back months. That’s the kind of headache no one can afford.

Even training feels the strain.

New operators in a foreign plant rely on clear, consistent instructions to get up to speed. When “heat treatment” morphs into something vague or unrelated in their language, learning curves stretch, and errors pile up. I’ve seen this firsthand—clients frustrated because their overseas teams couldn’t trust the manuals. It erodes confidence and slows everything down.

The ripple effects are real, but preventable.

Locking in a unified glossary early can keep terms steady across every document. Pair that with translators who get the nuts and bolts of additive manufacturing—people who know “ Raft” isn’t a typo for “raft”—and you’re ahead of the game.

My team’s tackled these messes before, straightening out tangled translations so workflows hum along smoothly.

Consistency isn’t glamorous, but it’s the backbone of getting precision from design to delivery, no matter the language.

Best practices for ensuring accuracy in additive manufacturing translations

Getting translation right in additive manufacturing is about strategy.

Over the years, I’ve learned a few practices that consistently deliver results, especially in a field where precision is non-negotiable.

First, start with a rock-solid glossary.

Terms like “Voxel” or “build envelope” need clear, agreed-upon translations that stay uniform across every document—design files, manuals, even training materials.

I’ve seen projects veer off course when “warping” got two different treatments in the same workflow. A glossary keeps everyone aligned, and it’s a step my team never skips.

Next, lean on translators who know the tech inside out.

This isn’t a job for generalists. Someone who understands the difference between “powder bed fusion” and “material jetting” won’t guess their way through a spec sheet—they’ll nail it.

I’ve worked with clients who tried cutting corners with generic services, only to end up with gibberish like “laser melting” instead of “selective laser sintering.” Pair that expertise with a tight feedback loop—engineers reviewing drafts early—and you catch slip-ups before they spread.

Context is another big piece.

Additive manufacturing spans industries, from aerospace to medical devices, and the language shifts slightly with each. A term like “post-processing” might mean sanding in one context and chemical smoothing in another. I’ve seen translations flop because the translator didn’t know the end use. The fix? Brief your team on the project’s scope—materials, machines, market—so they can adapt the words to fit the reality.

Don’t sleep on tools, either. Translation memory software can flag inconsistencies across languages, saving time and headaches.

But it’s not a crutch; it works because human expertise drives it.

Finally, test the output.

Hand a translated guide to an operator—or better yet, simulate the process yourself—and see if it holds up.

I remember a case where “bed leveling” came out too vague in Spanish, confusing a client’s team until we tweaked it.

Real-world checks catch what deskside reviews miss.

These steps aren’t flashy, but they’ve helped my clients launch products overseas with confidence.

Accuracy isn’t accidental—it’s built, layer by layer, just like the parts you’re making.

Choosing the right additive manufacturing translation partner: What to look for

Picking a translation partner for additive manufacturing can feel like a leap of faith, but it doesn’t have to be.

The right team can make or break your push into global markets, so knowing what to prioritize is key.

Start with expertise—deep, hands-on knowledge of the field.

You need someone who can tell “material extrusion” from “vat photopolymerization” without blinking. I’ve seen generic translators stumble over terms like “infill density,” turning precise instructions into guesswork.

A partner who gets the tech won’t leave you cleaning up costly misunderstandings.

Experience in your niche matters too.

Additive manufacturing isn’t one-size-fits-all—translating for aerospace parts differs from medical implants.

A team that’s handled powder bed fusion specs or topology optimization guides brings insight that generic agencies can’t match. I’ve worked with clients who switched to us after broad-stroke translators missed the mark on “recoater blade” nuances, delaying their production.

Look for a track record that mirrors your industry’s quirks.

Flexibility is another must.

Startups and SMEs often face tight deadlines or evolving docs as designs shift. A rigid partner who can’t pivot—or charges extra for every tweak—will slow you down.

I’ve had clients breathe easier knowing we can adjust on the fly, keeping their timelines intact.

Ask about their process: Can they handle rush jobs? Update a glossary mid-project?

That adaptability keeps your workflow humming.

Communication seals the deal.

You want a team that listens—really listens—to your needs, not one that churns out words blindly. I’ve sat with engineers to nail down what “support removal” means in their context, ensuring the translation clicks for the end user.

A good partner asks questions, offers feedback, and bridges the gap between your tech team and their linguists.

Check if they’re proactive—do they flag unclear source text before it becomes a problem?

Tools and tech round it out.

Translation memory systems and quality checks aren’t optional—they catch inconsistencies across languages fast. We’ve saved clients headaches by spotting “build plate” translated two ways in the same file.

But it’s not about flashy software; it’s how they wield it. A partner blending human skill with smart tools delivers accuracy without breaking the bank.

Look for these pieces—expertise, niche experience, flexibility, communication, and tech—and you’ve got a collaborator who’ll carry your vision across borders as precisely as your printers layer parts.

Best practices for preparing your additive manufacturing documents for translation

Prepping your additive manufacturing documents for translation can feel daunting, but a little groundwork goes a long way toward accuracy.

I’ve seen the difference it makes when clients hand over files that are clear and structured—it’s like giving your translator a clean slate to work with.

Start with clarity in the source text.

Terms like “overhang angle” or “print orientation” need to be precise and unambiguous in English before they cross borders. I’ve had to untangle specs where “support structure” was used vaguely, leaving room for guesswork in German or Mandarin.

Tighten up those definitions early, and you’ll save headaches later.

Consistency is your next ally.

If “layer height” pops up in a design file, don’t switch to “slice thickness” in the manual unless there’s a real distinction.

A quick fix is to create a style guide or glossary upfront. List your key terms and their meanings, then stick to them. It’s a small step that keeps translations on track.

Formatting matters more than you’d think.

Complex tables or nested lists in a maintenance guide can trip up even seasoned translators if they’re a mess.

Break things down—use bullet points, clear headings, and plenty of white space. It’s easier for humans and translation tools to parse, which means fewer errors creeping in.

Context is gold, too.

A translator who knows your document is for a metal 3D printer versus a polymer setup will handle “sintering” differently. I’ve had clients toss us files with zero backstory, and we’d have to guess if “cooling rate” tied to a machine or a post-process.

Spare your team the detective work—include a brief on the project’s scope, audience, and purpose. We’ve turned around sharper translations faster when we’ve got that insight.

Lastly, think about version control.

Additive manufacturing moves fast—designs tweak, specs shift. Sending an outdated file risks translating something obsolete.

Tag your files clearly and confirm they’re final before they hit the translation queue.

These habits aren’t glamorous, but they’ve helped my clients sail into new markets with docs that match their parts—precise, reliable, and ready to roll.

Leveraging technology: Tools and techniques for consistent, accurate AM translations

Technology can be a game-changer for nailing translations in additive manufacturing, but it’s all about using it wisely.

One tool I swear by is translation memory software—it’s like a brain that remembers how “build chamber” or “nozzle calibration” was handled last time.

This keeps terms consistent across manuals, spec sheets, and training guides. I’ve seen it save clients from the chaos of “fused filament fabrication” turning into three different phrases in Spanish—consistency like that builds trust with overseas teams.

Glossaries paired with tech take it further.

You can load a custom termbase into these systems, locking in translations for tricky bits like “shrinkage compensation” or “lattice structure.”

It’s a lifesaver for SMEs juggling multiple docs—everything stays uniform without endless back-and-forth.

I’ve had clients marvel at how fast we sync their language across markets, and it’s because we lean on these tools to catch drift before it starts.

Machine translation has its place, too, but it needs a human touch.

Raw output might butcher “powder bed fusion” into something unrecognizable—I’ve seen it happen.

The trick is post-editing by someone who knows AM inside out. We’ve polished rough drafts where “thermal debinding” got mangled, turning them into clear, usable French or Japanese.

It’s faster than starting from scratch and keeps costs down, which startups especially appreciate.

Collaboration platforms are another gem.

Engineers and translators can tag questions—like whether “overcure” fits a specific resin process—right in the doc. I’ve worked with teams across time zones this way, nailing down “support anchoring” for a German client in real time. It cuts confusion and speeds up delivery without sacrificing precision.

Quality assurance tech rounds it out.

Automated checks can flag if “extrusion multiplier” shifts meaning across files, but I always push for a final human pass.

Machines miss nuance—like cultural tweaks for “operator safety” in Korean versus English.

My team blends these tools with our know-how to deliver translations that don’t just work, but fit the workflow like a glove.

It’s about making tech amplify expertise, not replace it—keeping your AM projects sharp and global-ready.

Conclusion

Ensuring accuracy in additive manufacturing translation boils down to a few critical moves: embracing precision to dodge production hiccups, tackling complex terms with specialized know-how, and leaning on smart tools and prep to keep everything seamless.

These steps aren’t optional—they’re your ticket to keeping global teams aligned and projects on track.

Here’s something to chew on: research shows that 70% of international buyers trust a product more when its documentation is flawless in their language.

That’s not just clarity—it’s a competitive edge.

So, where do you stand?

Are your translations amplifying your innovation, or quietly holding it back?

In an industry racing toward ever-smarter manufacturing—like the push for AI-driven 3D printing—sloppy language can’t keep up.

I’ve seen the wins when it’s done right: clients hitting new markets with confidence, not chaos.

Let’s make sure your words layer up as perfectly as your parts—because in this game, precision isn’t negotiable.